In light of growing food insecurity in some parts of the world, agricultural machinery can play an important role in helping to efficiently achieve stable yields from crop production. Various types of agricultural implements are used depending on environmental conditions and manner of specific crop production in a given country or region.

Tractors are the primary machines used in crop production and handling work. By mounting implements to a tractor's drawbar or power take-off (PTO), fields can be cultivated, seeds can be planted, fertilizers and be spread, and agricultural chemicals can be applied.

Bearings are used throughout various components of the tractor such as the engine, transmission, wheel hubs, etc. under muddy working conditions and heavy load conditions.

Moreover, tractors and implements that are used in the vast fields of some farms in Europe and North America are huge, which place severe demands on the bearing. It is under such harsh working conditions that customers expect bearings to be highly reliable while offering superior cost performance.

NSK applies various technologies to the manufacture of bearings to meet customer needs, including heat-treatment technology for higher reliability under muddy working conditions, material technology for greater endurance under heavy-load conditions, and optimum design technology for longer service life. In constantly striving to enhance various technologies, NSK is a significant force that supports agricultural worldwide.

NSK Experience & Technology

Agricultural machinery bearings must offer a long service life while operating in harsh environments of mud, water, and heavy loads, while ensuring sufficient resistance against contamination from foreign debris. NSK offers various bearing products that meet these demands: the TM Bearing with a special seal, the Hi-TF Bearing that is manufactured with special material and heat-treatment technology, and EP Steel, which consists of an ultra-clean bearing steel that was developed and designed using NSK's proprietary technologies for material, tribology, and manufacturing. Through the application of these technologies, NSK is able to provide customers with bearings that offer unprecedented longer service life and are highly resistant to foreign matter.

NSK will continue efforts to further meet customer needs with bearings and bearing products using cutting-edge technologies.

Products

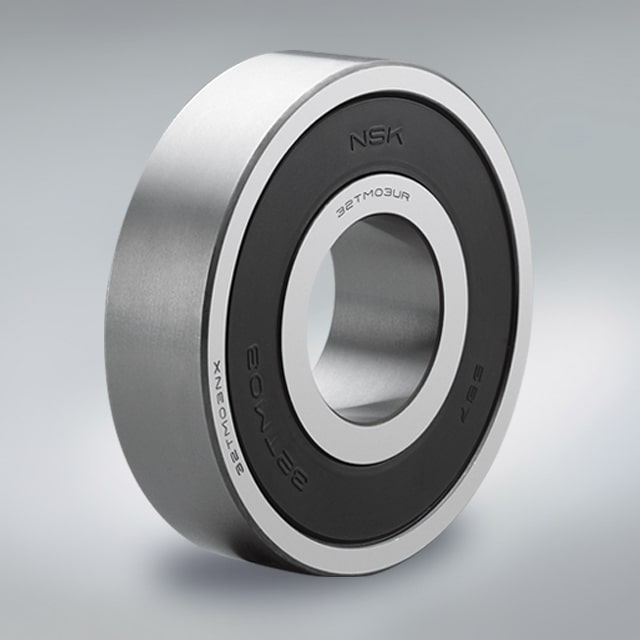

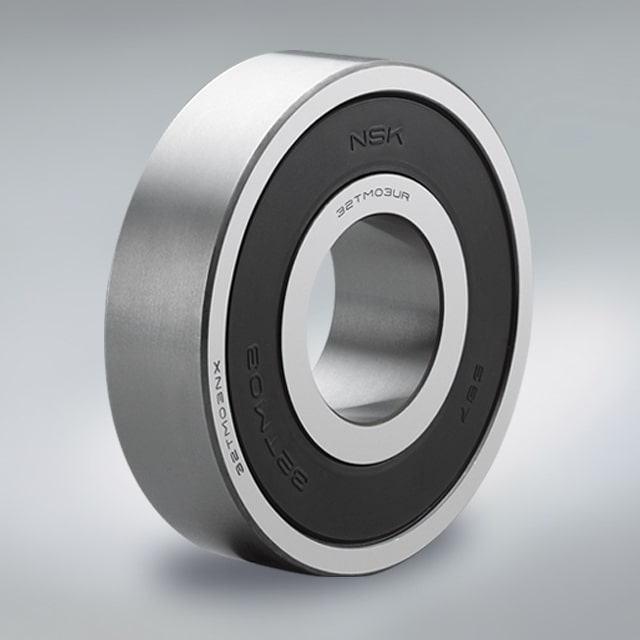

Deep Groove Ball Bearings

Deep Groove Ball Bearings

Rolling Bearings for Industrial Machinery: pp. C004-C047

Deep Groove Ball Bearings are the most common type of rolling bearing and are used in a wide variety of applications.

Large Hi-TF Bearings

Large Hi-TF Bearings

Hi-TF specification bearings offer superior performance, which is demonstrated with a long service life, superior wear and seizure resistance, and outstanding cost performance.

TM Series of Long-Life Sealed-Clean Ball Bearings

TM Series of Long-Life Sealed-Clean Ball Bearings

The TM series of bearings comes with a special seal-lip construction that allows the inflow of lubricating oil while preventing entry of foreign matter.

Thrust Ball Bearings

Thrust Ball Bearings

Rolling Bearings for Industrial Machinery: pp. C294-C311

Thrust ball bearings are classified into those with flat seats or aligning seats depending on the shape of the outer ring seat (housing washer). They can sustain axial loads but no radial loads. For single-direction thrust ball bearings, pressed steel cages and machined brass cages are usually used. The cages in double- direction thrust ball bearings are the same as those in single-direction thrust ball bearings of the same diameter series.

EP Steel (Super Long-Life, Highly Reliable Bearing Steel)

EP Steel (Super Long-Life, Highly Reliable Bearing Steel)

NSK has improved the steel manufacturing process by a applying a new technology for evaluating the presence of non-metallic inclusions, which has resulted in the development of a super long-life bearing steel. EP steel is a new generation of highly reliable bearing steel that minimizes variability of service life, which results in products that offer a more uniform and longer service life.

Needle Roller Bearings

Tapered Roller Bearings

Cylindrical Roller Bearings

Deep Groove Ball Bearings